Food Grade

Dry ice used to cool or freeze any type of food product must comply with food industry regulations. Continental Carbonic’s manufacturing processes ensure that our dry ice is “food grade” for customers in the airline catering, meat processing, food shipping and other industries where the highest sanitary conditions are necessary.

Food Distribution

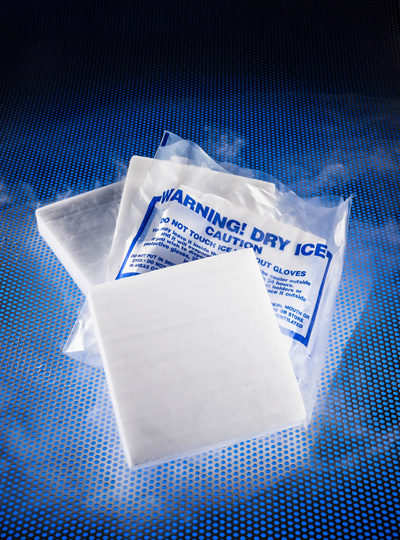

Cut block dry ice and pellet dry ice are both used in the food distribution industry. The predominant dry ice use in food distribution is to keep ice cream frozen in transit from distribution centers to commercial customers. Other food distribution applications include home delivery of groceries and off shore catering deliveries. A ten pound dry ice cut with 2″ x 10″ x 10″ dimensions is the most common form of dry ice used in the food distribution sector, and can either be delivered stacked in an insulated container with no packaging (“bare”), or individually packaged in poly bags. Some food distribution customers prefer to use bulk dry ice pellets or dry ice pellets packaged in poly bags. Most customers using bulk dry ice pellets get it packaged in poly bags containing 10 pounds of dry ice pellets each.

Insulated Containers

The finished product dry ice is delivered in either a 33 cubic foot, stainless steel lined insulated container or in larger fiberglass insulated containers. The 33 cubic foot containers hold approximately 2,000 pounds of cut block dry ice and 1,400 pounds of pellet dry ice. The largest fiberglass containers hold approximately 5,700 pounds of cut block dry ice. Full containers are weighed right before being loaded on our delivery truck and then delivered to the distribution center’s dock. Empty containers from prior deliveries are loaded back onto the truck. Upon return to the Continental Carbonic production plant, the empty containers are inspected for damage, repaired if necessary, and thoroughly washed and sanitized.

Product Quality

Continental Carbonic goes to great lengths to minimize the risk of product contamination. We adhere to strict maintenance and sanitization programs for our dry ice production equipment. We require our floor personnel to wear hair nets and anti-bacterial smocks and employ food grade cleanliness practices. Liquid carbon dioxide and dry ice are periodically tested to assure tight product specifications are being met. Digital video cameras monitor the production floor at each of our plants. Insulated containers are thoroughly cleaned and sanitized upon their return to our plants and lids are shrink wrapped once containers are filled. These practices result in Continental Carbonic being able to deliver the highest quality cut block and pellet dry ice in the industry.

On Time Deliveries

Our food distribution customers require timely delivery of dry ice to allow their distribution centers to meet their outbound food shipment schedules on an uninterrupted basis. Continental Carbonic managers stay in close contact with their customer counterparts to insure timely and accurate communication of orders and adjustments.